Fandi Meng1, Rui Liu1, Jianning Chi2, Li Liu1*

1School of Materials Science and Engineering, Northeast University, Shenyang, 110819, China;

2College of Robotics, Northeast University, Shenyang, 110819, China

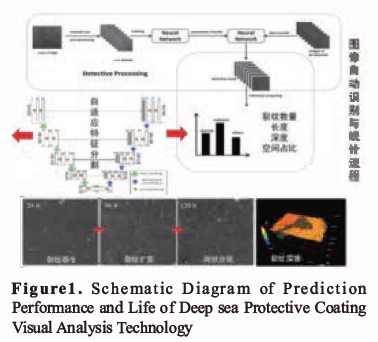

EXTENDED ABSTRACT: In recent years, with the high development of material genetic engineering technology, precise prediction of material properties can be achieved based on fine visual analysis technology. As one of the traditional protection methods, the protective coating has been difficult to achieve accurate prediction of coating life because of its service process covering many factors and complex failure factors. Collect a large number of topographic images during the service of the coating, establish image pre-processing, screening, standardization and other pre-processing processes through visual analysis technology, and then establish a multi-layer convolution neural network (8-10 layers) to automatically identify the characteristic phase of the signal to distinguish the coating, coating/substrate interface and corrosion product layer. Based on the measured results of service performance of coatings, this neural network is used to establish an effective network association between image quantitative analysis and performance quantitative analysis, and to establish a simulation network for reconstruction of coating change images under different service time conditions, so as to realize the simulation of coating service performance image status and life prediction. The visual analysis technology can be applied to high temperature protective coatings, organic protective coatings and wear-resistant protective coatings. Among them, the quantitative analysis,identification and life prediction of organic protective coatings in the environment of 600m deep sea fluid (3.5 m/s flow rate) are preliminarily realized through visual analysis image acquisition of deep-sea organic protective coatings, combined with the aid of EIS signal analysis. This technology can also assist in the design and development of protective coatings, and has broad application prospects in the future.

Keywords: Visual analysis technology; Protective coating; Failure; Life prediction

REFERENCES

[1] Rui Liu, Minghao Wang, Huan Wang, Jianning Chi, Fandi Meng, Li Liu* and Fuhui Wang, Recognition of NiCrAlY coating based on convolutional neural network, npj Materials Degradation (2022): 7

Prof. Li Liu has completed her PhD from Institute of Metal Research, Chinese Academy of Sciences. She is now a professor and doctoral supervisor of the School of Materials Science and Engineering, Northeast University. She was supported by " Excellent Young Scientists Fund" of National Natural Science Foundation of China. She has been engaged in marine corrosion and protection research for a long time. and has published more than 100 papers in international academic journals.