Data Driven Approach on Development and Design of Metallic Glasses

Jie Xiong1, Tong-Yi Zhang1, 2*

1 School of Materials Science and Engineering, Harbin Institute of Technology, Shenzhen, China

2 Material Genome Institute, Shanghai University, Shanghai, China

EXTENDED ABSTRACT: Metallic materials are widely used due to their excellent mechanical properties, while the conventional metallic materials cannot meet the requirements of future engineering applications. The amorphous structure of metallic glasses results in distinct mechanical and physical properties that are not exhibited by conventional crystalline alloys [1]. Around 1,000 metallic glasses have been developed in the last 40 years. However, the relationship between mechanical property and chemical composition in metallic glasses has not been established due to the poor understanding of the underlying physics. At the moment, it is difficult to develop an analytic model to design a new bulk metallic glasses. As a result, a trial-and-error based design method is extremely challenging [2].

Along with the fast development of artificial intelligence, the materials informatics is rapidly becoming popular in the field of materials science. Integrating artificial intelligence with materials science and engineering may accelerate the design and discovery of advanced materials. Recently, machine-learning (ML) approaches have been utilized to predict the properties of metallic materials. Several studies have used ML approaches to identify the correlations between glass-forming ability and the experimentally measured properties of an alloy. These studies thus confirmed that ML methods were reliable and efficient in discovering new metallic glasses and predicting their properties [3-5].

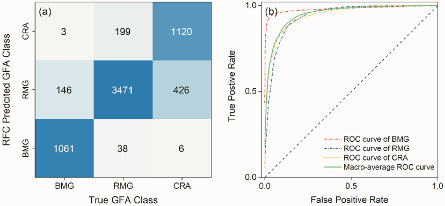

In this work, we developed and validated an ML framework based on decision tree-ensemble algorithms for the prediction of glass-forming ability and design of metallic glasses. A dataset of metallic glasses was created by collecting data from several related studies. First of all, random forest models are developed to identify whether an alloy can form an amorphous bulk (i.e., a BMG) via rapid cooling (e.g., by copper-mold casting, injection molding, or suction casting), an amorphous ribbon (i.e. a ribbon metallic glass, or RMG), or a crystalline alloy (CRA). Fig.1a shows the confusion matrix of the built model, which has an accuracy of 88.13%. In this context, precision is the ratio of relevant samples to retrieved samples, 1,151 alloys were classified as BMG alloys by the ML model, and 1,073 were labelled as BMGs in our dataset, meaning that the precision of BMG classification was 93.2%. Another widely used measurement, the receiver operating characteristic (ROC) curve, is shown in Fig.1b. The area under ROC curve (AUC) of classifying crystalline alloys and amorphous alloys classifications is 0.95, and the AUC of distinguishing BMGs from other alloys can reach 0.98. This excellent prediction accuracy indicates that our model can be used to discover new glass- formers. In addition, symbolic regression is conducted to analysis glass-forming abilities, three prerequisites for forming BMGs are (1) a high mixing entropy, (2) a high average thermal conductivity, and (3) an appropriate negative mixing enthalpy, approximately equal to -28 kJ/mol.

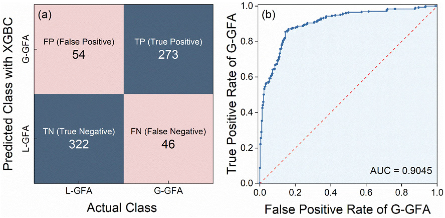

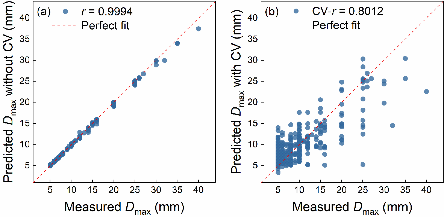

Then, classification will be conducted on the data to classify the good glass-forming ability and limited glass-forming ability BMGs. The detailed classification results are shown in Fig.2a, confusion matrix of the XGBoost algorithm with cross-validation, the overall predictive accuracy can reach 85.61%. Fig.2b shows the ROC curve of classifying good glass-forming BMGs from limited ones, the AUC value is 0.9045, indicating the outstanding classification of the XGBoost classification model. Finally, the critical casting diameter (Dmax) of good glass-forming BMGs are predicted with an XGBoost regression model. Fig.3(a, b) shows the measured Dmax values versus the predicted values on the training data set and the testing set, respectively. As expected, the prediction of the XGBoost regression model on the training set has an extremely high correlation coefficient of 0.9994, meaning that the model is perfectly trained, and the correlation coefficient remains 0.8012 under the 10-fold cross-validation.

The ML models outperformed conventional GFA criteria, as it had a much higher predictive accuracy. The generalization capabilities of ML models are better than conventional models as well, meaning ML models can guide the discovery and understanding of novel metallic glasses.

Fig.1. The performance of the random forest model (a) the confusion matrix and (b) the ROC curve.

Fig.2. The performance of the XGBoost classification models (a) the confusion matrix and (b) the ROC curve.

Fig.3. The predicted Dmax values with ML model verse the actual values (a) without and (b) with validation.

Dr. Xiong has completed his PhD at the age of 27 years from the Hong Kong Polytechnic University. He is postdoctoral researcher in Harbin Institute of Technology, Shenzhen, China. His research interests are applications of materials informatics on metallic materials.