Research on failure diagnosis method based on data catastrophe analysis

Hongyun Luo1*, Qianqian Tian2

1 School of Materials Science and Engineering, Beihang University (BUAA), Beijing, 100091, China

2 School of Energy and Power Engineering, Beihang University (BUAA), Beijing, 100091, China

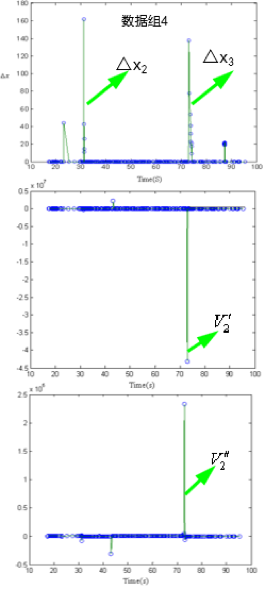

EXTENDED ABSTRACT: Data has become an important driving force for social development in the digital age, and the application of big data information mining technology in retail, finance, urban and medical fields is expanding, achieving significant advantages and bringing lucrative profits to these industry. In the field of failure analysis, it is now mainly used to analyze the pooled multiple data sources and identification results combined with failure experience and microscopic images to help failure analysis, or production data and failure analysis knowledge fusion modeling applied to process problems as an assist in troubleshooting. The application of big data mining and analysis needs to be embedded. The damage monitoring information of materials and components is very useful big data information, and its effective use can not only enable the development of big data mining theory and technology related to failure analysis and prediction prevention, but also useful for the safety and reliable use of materials. The damage and failure process of materials can cause abrupt changes in monitoring data, so this paper proposes to use the catastrophe theory to analyze the discontinuous jump phenomenon in the damage process and realize the mining analysis of big data of monitoring process. The swallowtail catastrophe and the cusp catastrophe model are mainly introduced. For the swallowtail model, the swallowtail catastrophe analysis of a single research object (fatigue damage data) is firstly introduced, and the results show that the catastrophe model can accurately identify the transition point between the stable extension stage of the crack and the destabilization extension stage, and the analysis by comparing the scanned fractogram and the test data reveals that the crack length basically matches, and the micromechanism before and after the catastrophe point changes from the dislocation activity in the plastic zone into the microporous microcrack between ligament tears, i.e., the analysis results of the swallowtail catastrophe were verified. And the transition point is earlier than the transition point of crack extension stage identified by Pairs formula; then the multi-study object analysis of swallowtail catastrophe is introduced, and the results show that the sudden change of heat loss rate of dynamic equipment is caused by the sudden change of each temperature parameters. The increase of ambient temperature in summer causes the rise of water temperature and the abrupt change of heat loss rate, which is not related to the wear of components, i.e., the multi-study object abrupt change correlation analysis is used to achieve the discrimination of failure causes. However, there are some problems when the current basic catastrophe model dealing with damage problems, there are more catastrophe interference points and the standard deviation of the catastrophe location error is also larger which makes the application more difficult of catastrophe theories on failure analysis . For this reason, this paper proposes a rechecking model based on the cusp catastrophe model. The results revealed that in the cusp catastrophe analysis in single/multiple study subjects, the rechecking model not only eliminates the redundant interfering catastrophe points identified by the classical model with high self-adjustment adaptation ability, but also achieves early catastrophe prediction in (deformation) damage, as shown in Figure 1. The results of this paper can further enrich the mining and analysis of big data in the field of failure analysis, and lay the foundation for the application of big data in material genetic engineering. The deep integration of physical entities and digital voxels contributes to the high-quality development of failure diagnosis.

Figure 1. Cusp mutation analysis of data set 4

Prof. Hongyun Luo is currently a professor and doctoral supervisor in the School of Materials Science and Engineering of Beihang University. She has long been engaged in the research of material damage mechanism, characterization and probabilistic integrity related to continuous dynamic integrated monitoring and detection of material and structural defects (metallic and biological), as well as the formation mechanism of surface integrity of low plasticity processed materials. She has undertaken and participated in a number of scientific research tasks entrusted by national and enterprises, won 5 provincial and ministerial awards, edited and participated in the preparation of 4 works, published more than 100 articles and more than 20 invention patents have been approved.