High-throughput preparation and electrochemical screening of nanocrystalline Fe-Cr-Ni material libraries with homogeneous element distribution

Kewei Gao1*, Youpeng Song2, Luchun Yan1, Xiaolu Pang1, Yanjing Su2, Lijie Qiao2

1 School of Materials Science and Engineering, University of Science and Technology Beijing, Beijing, 100083, China

2 Institute for Advanced Materials and Technology, School of Materials Science and Engineering, University of Science and Technology Beijing, Beijing, 100083, China

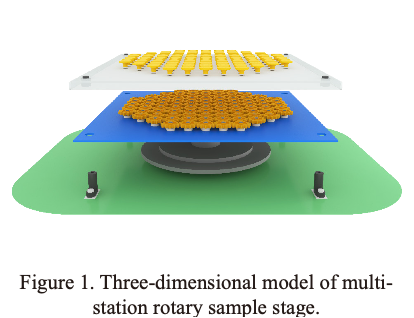

EXTENDED ABSTRACT: The vast compositional space of multi-component alloys constitutes a large challenge for materials discovery. Alternatively, high-throughput methods have been widely applied to synthesize the combinatorial material libraries and facilitated an assessment of the material’s corrosion behavior as a function of composition. Magnetron co-sputtering is one of the commonly used high-throughput preparation methods. However, for a specific alloy composition in the combinatorial material libraries synthesized by this method, its element distribution is not uniform, because the sample stage is fixed during the deposition process. When the material libraries are used for high-throughput corrosion screening, the problem of galvanic corrosion usually exists, since the different alloy composition ratio has different corrosion potential, which greatly reduces the evaluation accuracy of alloys’ pitting corrosion resistance. Moreover, the traditional and mature testing methods are not suitable for the characterization of such combinatorial material library samples, and it is usually necessary to develop the corresponding high-throughput micro-analysis techniques. Here, we present a high-throughput approach for preparing multi-component alloy material libraries with homogeneous element distribution. In the process, all alloy elements were simultaneously deposited on a multi-station sample stage with 97 independent micro-components that can rotate synchronously; thus, a large number of nanocrystalline alloy samples with homogeneous element distribution can be fabricated by one sputtering process. Using this approach, we fabricated 22 nanocrystalline Fe-Cr-Ni alloy compositions and investigated their pitting corrosion resistance by electrochemical experiments. The relationship between chemical compositions and pitting corrosion resistance was rapidly established, and the reasons for different corrosion resistance between different alloy compositions were analyzed. The experimental methodology adopted in this work can also be applied to preparing other multi-component alloy material libraries.

Professor Kewei Gao, Department of Materials Physics and Chemistry, University of Science and Technology Beijing. She has long been engaged in the research of corrosion of metal materials and environmental fracture. More than 200 papers have been published, including more than 100 in SCI. She was supported by the New Century Excellent Researcher Award Program from Ministry of Education of China and the Beijing Science and Technology Star program. She has presided over several National Natural Science Foundation projects, National Key R&D Programs and 863 projects.