Development of AI-assisted computational platform for accelerating design and discovery of novel high-temperature alloys

Xingjun Liu1,2,3*, Shengkun Xi1,2, Jinxin Yu4, Rongpei Shi1,2

1 School of Institute of Materials Genome and Big Data, Harbin Institute of Technology, Shenzhen, 518055, PR China

2 School of Materials Science and Engineering, Harbin Institute of Technology, Shenzhen, 518055, PR China

3 State Key Laboratory of Advanced Welding and Joining, Harbin Institute of Technology, Shenzhen, 518055, PR China

4 College of Materials, Xiamen University, Xiamen, Fujian, 361000, PR China

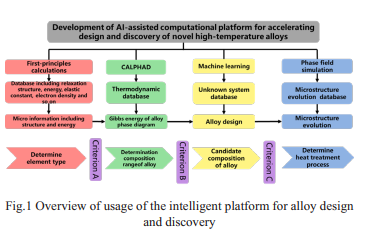

EXTENDED ABSTRACT: Superalloys possess a unique combination of outstanding mechanical response, excellent oxidation and corrosion resistance at elevated temperatures. Co-based superalloys with high specific yield strength and corrosion resistance and Nb-Si based ultrahigh-temperature alloys capable of functioning at temperatures above 1200 ℃ represent a new opportunity for high-temperature alloy developments in aerospace and energy applications. Co-based superalloys are strengthened by coherent L12 ordered precipitate in a disordered face-centered cubic matrix, while Nb-Si based ultrahigh-temperature alloys are strengthened through the dispersion of eutectic Nbss+Nb5Si3 phases. Controlling stability of strengthening phases through alloying and processing optimization is critical for alloy development. However, analysis of high-dimensional composition space and identification of correlations among the composition processing-structure-property relationship based on conventional trial-and-error approach are often a time- and resource-intensive endeavor. Herein, we develop and deploy an “AI-assisted Intelligent computational platform for accelerating composition screening and process optimization for the design and discovery of new Co-based superalloys and Nb-Si based ultrahigh-temperature alloys". The platform is built upon tree widget and XML technology and implemented in C++, and integrates the first principle calculation module, phase diagram calculation module, machine learning module and phase field simulation module. The platform enables high throughput multi scale simulations for predicting crystal structures and compositions of phases, microstructure evolution and the associated heat treatment schedules to realize the design and discovery of novel Co-based superalloys and Ni-Si-based ultrahigh-temperature alloys. Autonomous high-throughput data analysis and screening with on-the-fly decision making is guided by domain knowledge in materials science. 21 types of transition elements are adopted for doping and the associated formation enthalpies are calculated, and the results indicate that the addition of Ni, Al, W, Ti, Ta, Cr and the addition of Ti, Al, Cr, Mo are effective in improving the phase stability of the strengthening phases in Co-based and Nb-Si-based high-temperature alloys, respectively. Composition screening for these two types of alloys is undertaken within the established in-house thermodynamic databases, from which, alongside with thermodynamic criteria, 273 alloy compositions with melting temperature of phase higher than 1150 are identified from all 41701 possible candidates for Co-based alloys, and 270 alloy compositions with melting temperature of Nb5Si3 phase higher than 1300 are screened out of all possible candidates for Nb-Si-based alloys. Through simulating microstructure evolution for these two types of alloys as a function of aging temperature and time, the optimized processing routes are determined to be aging 12 h at 1200 and aging 20 h at 1250 for Co-based and Nb-Si-based alloys, from all possible 64 combinations of aging temperature and time. Two different alloys were identified with novel compositions and experimentally validated in terms of phase fraction, melting point and mechanical properties of the strengthening phases. In summary, two types of high-temperature alloys with desired combination of properties at elevated temperatures have been successfully discovered though using the platform. Through simulations spanning multiple scales, the platform enables systematic design regarding alloying elements, composition ranges and processing parameters, thereby allowing for efficient discovery of novel Co-based and Ni-Si-based alloys. The applications of this platform will greatly accelerate rates of development, discovery and deployment for these two types of high-temperature alloys. Fig.1 Overview of usage of the intelligent platform for alloy design and discovery.

Professor Xingjun Liu received his Ph.D. in Materials Science and Engineering from Tohoku University (Japan), and is now the dean of Materials Genome and Big Data Institute at Harbin Institute of Technology (Shenzhen). Prof. Liu was the winner of Distinguished Young Scholars from National Science Foundation China, national leading Talent at Shenzhen. He is now a member of the National Advisory Committee for New Materials Development, Deputy Director of Space Materials Committee of Chinese Society of Space Sciences, Deputy Director of Phase Diagram Professional Committee of Chinese Physical Society, Executive Director of Chinese Society for Materials Research, Member of the editorial board for the journals of "Materials China" and " Transactions of Nonferrous Metals Society of China". He has published about 350 articles in peer-reviewed journals such as Science, Nature Comm., Phys. Rev. Lett, PNAS, Small, Acta Mater, to name a few, which has been cited more than 5,000 times. He has more than 51 authorized national invention patents and won more than ten academic awards at both domestic (provincial and ministerial) and international levels