Data-driven materials design and property extraction from simple testing

Jinglei Yang*, Cheng Qiu

The Hong Kong University of Science and Technology, Hong Kong SAR, China

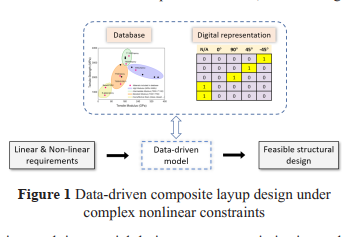

EXTENDED ABSTRACT: Material or structural design problems are usually in the very complex and nonlinear domain. Taking fiber composite materials as an example, they have good elasticity and brittleness in the fiber direction at the macro scale, but their damage, failure and fracture problems are largely related to the interface and microstructure at the micro scale, showing the complexity of multi-parameter effects across scales. The scientific problems of structural design can be summarized as the forward prediction and inverse design problems of preparation material microstructure-macrostructure performance. The research of material preparation process is usually limited by the lack of in-situ observation means, and the means of simulation analysis can only be verified from indirect phenomena or data comparison. Taking the material preparation of microcapsules as an example, the polymerization reaction of the material at the interface usually occurs on the micron and millisecond scales. Even the advanced Micro-CT can hardly capture the material forming process. Simulation can only be validated through indirect phenomena after the microcapsule is formed, thus lacking verification of the forming process. Meanwhile, the modeling process is complicated. The data-driven approach is an effective surrogate model to solve the above-mentioned problems. Firstly, data-driven algorithms can efficiently and effectively find any hidden non-linear correlation between input and output. Secondly, as a summary and inductive method, datadriven algorithms can also summarize parameter influence that can be analyzed and understood from indirect observation data, and even fit simple formulas. Based on the above ideas, we have done the following work in material design, structure optimization and material performance parameter mining: (1) The general design criteria of composite materials were digitized, and the linear and non-linear design requirements were used as constraints to establish data-driven composite layup design method; (2) Data-driven topological optimization design of lightweight structure with minimum flexibility function as the design goal; (3) Mining fracture-related parameters at meso-scale from the macroscopic performance parameters of composite materials under simple loading condition. The above works have shown that data-driven analysis methods can play a significant role in the complex nonlinear problems of material and structural design.

Professor Yang’s research interests range from chemistry, materials engineering to mechanics, including using data-driven approach to design and fabricate multifunctional materials and composite structures and mechanical properties.