Yang Li, Su Hang

China Steel Research Digital R&D Center, Beijing, 100081, China

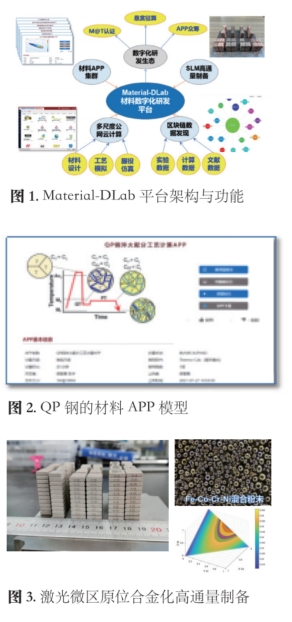

EXTENDED ABSTRACT: In response to the challenges of computational resources and data sharing in innovative research and development of metal materials, we have established a comprehensive material digital R&D platform called Material-DLab, in which integrating multi-scale public cloud computing, material APP cloud-native, high-throughput preparation, and research data sharing. Based on the high-performance computing and massive storage with ten thousand cores and petabyte-level capacity, our platform supports remote computing, queuing computing, and mobile computing for over 40 types of specialized software for materials and processes. It can simultaneously nm more than 40 large-scale computing tasks and handle over 500 concurrent design and data tasks. We have also built specialized material APP clusters and cloud-native systems to address the challenges of knowledge integration and accumulation for materials/process and computational engineers. The platform supports cloud-based generation and computing of various material APPs, inclu中ng first principles, materials phase 山agranis, finite element analysis, metallurgical fluids, and machine learning.

Based on this platform, we have conducted extensive叩tal R&D work in materials calculation, process simulation, service simulation, and machine learning, focusing on product development, product upgrades, and process optimization in the fields of steel, high-temperature alloys, and functional metal materials. For instance, we addressed the design and development challenges of QP steel for the third-generation automobiles at Angang Beijing Research Instit:Jite by developing predictive models and APPs, calculating the QT/PT temperature range, and predicting the inclusion content. In response to the material development needs of the world's first 25 cubic meter high-pressure hydrogen storage tank at SINOPEC, we conducted material selection design through computation and experiments based on the platform, and within only six months, we developed engineering solutions and successfully completed industrial trial production, assessment, and construction of the test vessel. To tackle the micro-crack issue in high-temperature alloy with additive manufacturing at CISRI-Gaona, we utilized material calculation, high-throughput preparation and characterization, and machine learning opt血zation to complete the selection of over 40 types of materials and 200 comb血tions of processes within 2 months, efficiently accomplishing composition and process optimization work that used to take 2-3 years. AT &M Technology has conducted inter山sciplinary digital talent cultivation and product process optimization based on this platform in the past year, achieving a 100% 叩nealing structure qualification rate for Cr-type mold steel products(previously 50%), a 100% shrinkage qualification rate (:C:6mm) for cast high-temperature master alloy products(previously 80%), and an 85% qualification rate for magnetic deviation of NdFeB permanent magnet products(previously 71 %). To date, the platform has achieved more than 50,000 online computing tasks, uploaded over 30,000 experimental data, and fostered over 700 crowdfunded material APPs.

Keywords: Material Digital R&D; Cloud Computing Platform; High-Throughput Preparation; Material APPs;

Yang Li, senior engineer, PhD, graduated from RWTH Aachen University in Germany. She is mainly engaged in design and research of new materials, research and application of MGE technology, multi一scale integrated computing tec血ology, and material digital research and development tec加ology. She is

rficient in multi-scale calculatio te加ques for matenals, mcluding CALPHAD, phase field models, finite .element _ .simulations, etc. and utilize those methods into material design, process simulation, and

service simulation. In past 5 years, she has led and participated in more than 10 research projects form National Key R&D Program of China , Ministry of Industry and Information Tec加ology and National Natural Science Foundation, and more than 10 projects from enterprise horizontal cooperation. She has published over 20 papers in domestic and foreign journals, and applied for more than 10 patents.